Services

Dhanshika Networking India Pvt Ltd

Our Services

Dhanshika Networking India Pvt Ltd Work in Many Field and has Many Years of Experience in all these Fields

Civil Construction

we provide comprehensive civil construction services tailored to meet the evolving demands of modern infrastructure.

Read More

Electrical & Networking Service

we specialize in delivering reliable, efficient, and future-ready electrical and networking services to meet the dynamic needs of residential, commercial, and industrial projects.

Read More

Silo Installation

Our team ensures safe, durable, and high-performance silo systems that optimize space and maintain material integrity.the storage needs of various industries including agriculture, food processing, cement, chemicals, and more.

Read More

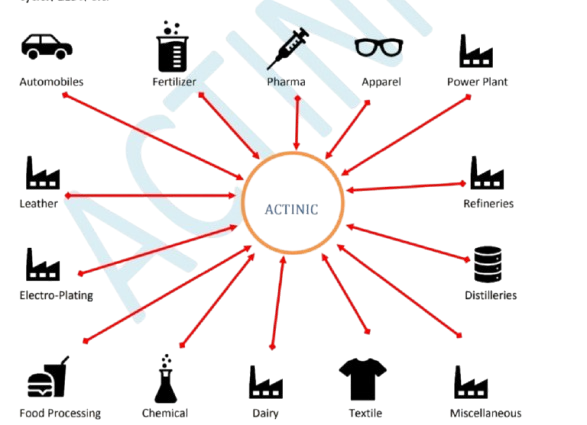

Water Solution ETP, STP

we provide reliable and efficient water treatment solutions including Effluent Treatment Plants (ETP) and Sewage Treatment Plants (STP) for a wide range of industries and infrastructure projects.

Read More

Bagging Machine Sale & Installation

we offer end-to-end solutions for bagging machine sales and installation across multiple industries such as cement, chemicals, food, fertilizers, and grains.

Read More

Mechanical Engineering

we offer a comprehensive range of mechanical engineering services designed to support industrial growth, plant optimization, and equipment efficiency.

Read More

The treatment of different effluents varies with the type of effluent. Wastewater enters the effluent treatment plant and goes through several processes before effluent goes into the environment. Industrial effluent treatment plant process includes the following stages:

1.Screening:

This is the first unit operation Air of that occurs in wastewater treatment plants. cycle time A screen is a device with uniform openings, and its purpose is to remove large floating solids.2.Sedimentation:

It is a physical water treatment process using gravity to remove suspended solids from water. Neutralization: Motor on Air on The pH of the wastewater is maintained between 6 and 9.3.Coagulation:

A coagulant is added to the 45, 50 and 55 min/h Cycle time: 10, 20, wastewater to help small solid particles settle into larger masses.4.Flocculation:

A chemical flocculent is added to help particles collide and form larger flocs that settle out more quickly.5.Clarification:

These are tanks built with mechanical means for continuous removal of Suprnatant zone solids being deposited by sedimentation Settling stage before biological treatment.6.Filtration:

Water is passed through a filter made of sand and gravel layers to remove particulates.7.Disinfection:

Chemicals like chlorine, ultraviolet light, or ozonation are used to kill harmful bacteria and viruses.8.Sludge treatment and disposal:Sludge is

dewatered

and

treated

before being

disposed of.

These works include the following:

At Dhanshika Networking India Pvt Ltd, we also provide various Settlers / Clarifiers,

Sewage Treatment Plants, Recycles, ZLDs, etc.

Dhanshika Networking India Pvt Ltd, being a single window solution for all, provides all

spares, consumables, equipment's, accessories, etc. being required for Effluent Treatment

Plant.

Dhanshika Networking India Pvt Ltd also provides the sale of new plants, expansions of

existing plants, retrofits of existing plants, Installation & Reinstallation of new &

existing Plants, commissioning & Re-commissioning of New & existing Plants. We also offer

to our customers Annual Maintenance contract & Operation Maintenance Contracts.

Zero Liquid Discharge

Recovery and recycling of wastewater has become a growing trend in the past decade due

to rising water demand. Wastewater reuse not only minimizes the volume and

environmental risk of discharged wastewater, but also alleviates the pressure on

ecosystems resulting from freshwater withdrawal. Through reuse, wastewater is no

longer considered a " pure waste" that potentially harms the environment, but rather an

additional resource that can be harnessed to achieve water sustainability.

Zero Liquid Discharge (ZLD) is a ultimate cutting-edge wastewater treatment process

developed to completely eliminate all liquid discharge from a system. The goal of a zero

liquid discharge system is to reduce the volume of wastewater that requires further

treatment, economically process wastewater and produce a clean stream suitable for

reuse.

Zero-liquid discharge (ZLD) is a new innovative approach that aims to provide the highest

water recovery and the lowest disposable waste volume through Multistage processes

including: